| | CAUTION: | |

|---|

| The brushes must not ride the ridges or insulations between the slip rings. If the brushes are not riding the slip rings, shims am provided for installation behind rear cone or brush housing as required. With the brushes correctly positioned, install safety pins to brush housing snaps. | |

|

| | NOTE: | |

|---|

| If brushes protrude 3/8" or less from brush holder, they should be replaced. | |

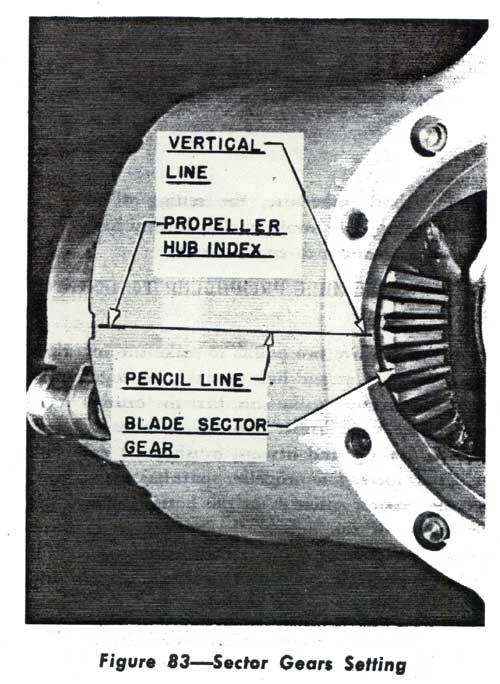

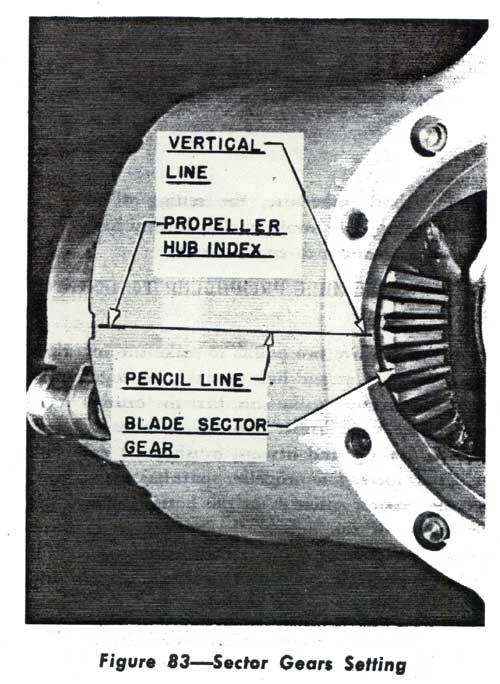

(d) SETTING OF BLADE SECTOR GEAR.As the propeller blade is rotated into high pitch angle, the leading edge of third tooth of each blade sector gear is brought up to vertical center line as explained in paragraph (7)(~c), this Section. (See Fig. 83.)

| | NOTE: | |

|---|

| A wooden blade wrench should be used if blades are stiff or difficult to turn. | |

|

|

| | WARNING: | |

|---|

| If the blades are not properly set or positioned, the power unit will not mesh into blade sector gears. The above blade positioning is for P-40N series starting with A. F. No. 42-104429. | |

(9) TO INSTALL POWER UNIT SEALS AND CONTACT POINTS.

(d) Before assembling to hub, make sure that the felt or grease seal has been dipped in castor oil. This will prevent moisture seeping through the breather holes of power unit housing and severe corrosion inside of power gear. Place felt or grease seal into power gear opening. Place neoprene seal in seal groove of adapter plate just to rear of power gear.

|